Packaging plays a crucial role in protecting PRODUCTS and ensuring their quality. When choosing packaging materials, cost-effectiveness becomes a key factor. You want a solution that balances affordability with performance. This raises an important question: Is plastic film the most cost-effective option available? Understanding its value compared to other materials can help you make informed decisions for your packaging needs.

Factors Influencing the Cost-Effectiveness of Plastic Film

Production Costs

The production process plays a significant role in determining the cost-effectiveness of any packaging material. Plastic film stands out due to its efficient manufacturing methods. You benefit from its streamlined production, which requires less time and fewer resources compared to materials like glass or metal. Manufacturers can produce large quantities of plastic film quickly, reducing overall costs. This efficiency translates into savings for businesses and consumers alike.

Additionally, advancements in technology have further optimized the production of plastic film. Modern machinery minimizes waste during manufacturing, ensuring that every resource is utilized effectively. By choosing plastic film, you gain access to a material that combines affordability with high production efficiency.

Material Costs

The raw materials used in packaging significantly impact its cost. Plastic film, often made from polyethylene or polypropylene, offers a cost advantage over alternatives like paperboard or aluminum. These raw materials are not only affordable but also widely available, ensuring consistent supply and stable pricing.

When you compare plastic film to other materials, you’ll notice that it often requires less material to achieve the same level of protection. For example, a thin layer of plastic film can provide excellent barrier properties, while thicker layers of other materials may be necessary to achieve similar results. This reduction in material usage lowers costs and makes plastic film a more economical choice for many applications.

Energy Efficiency

Energy consumption during production and transportation also affects the overall cost-effectiveness of packaging materials. Plastic film excels in this area due to its lightweight nature. You’ll find that transporting plastic film requires less energy compared to heavier materials like glass or metal. This reduction in energy use leads to lower shipping costs and a smaller carbon footprint.

Moreover, the energy required to produce plastic film is relatively low. Modern manufacturing processes have been designed to maximize energy efficiency, further reducing costs. By selecting plastic film, you’re choosing a material that not only saves money but also supports energy conservation efforts.

Waste Management

Waste management plays a crucial role in determining the cost-effectiveness of packaging materials. When you choose plastic film, you benefit from its ability to minimize waste during both production and disposal. Manufacturers have developed processes that reduce material waste, ensuring that resources are used efficiently. This not only lowers production costs but also helps you contribute to sustainable practices.

Plastic film often generates less waste compared to bulkier materials like cardboard or glass. Its lightweight and compact design allow you to use less material while still achieving excellent protection for your products. This reduction in material usage means fewer resources are discarded, which can significantly lower waste management expenses.

Recycling options for plastic film have also improved over the years. Many facilities now accept certain types of plastic film for recycling, giving you an opportunity to reduce landfill contributions. By participating in recycling programs, you can further enhance the cost-effectiveness of this material while supporting environmental conservation.

Additionally, advancements in biodegradable and compostable plastic films offer promising solutions for waste reduction. These innovations allow you to dispose of packaging more responsibly, aligning with growing consumer demand for eco-friendly practices. Choosing such options can help you balance cost savings with environmental responsibility.

Comparative Analysis of Plastic Film and Other Packaging Materials

Cost Comparison

When comparing packaging materials, cost often becomes the deciding factor. Plastic film offers a clear advantage in terms of affordability. Its production process is efficient, and the raw materials, such as polyethylene, are inexpensive and widely available. You can achieve significant savings by using plastic film, especially for large-scale packaging needs.

Other materials, like glass or metal, tend to have higher production costs. These materials require more energy and time to manufacture, which increases their price. Paper-based packaging, while often seen as eco-friendly, can also be costly due to the resources needed for its production and the additional weight it adds to shipping.

Plastic film’s lightweight nature further reduces transportation expenses. Shipping costs are calculated based on weight, and heavier materials like glass or cardboard can quickly increase these expenses. By choosing plastic film, you minimize these costs, making it a more economical option for businesses focused on budget efficiency.

Durability and Protection

Durability plays a crucial role in packaging. You want materials that protect products effectively during storage and transportation. Plastic film excels in this area. Its flexibility and strength allow it to withstand pressure and impact without tearing or breaking. This durability ensures that your products remain safe and intact.

Glass and metal, while durable, are prone to breakage or denting under certain conditions. Paper-based materials, such as cardboard, may lose their structural integrity when exposed to moisture. Plastic film, on the other hand, provides excellent resistance to water and other environmental factors. It acts as a reliable barrier against moisture, dust, and gases, preserving the quality of your products.

Additionally, plastic film’s sealability enhances its protective qualities. You can use it to create airtight seals, which help extend the shelf life of perishable goods. This feature reduces waste and ensures that your products reach customers in optimal condition.

Environmental Impact

Environmental concerns often influence packaging decisions. Plastic film has faced criticism for its impact on the environment, but advancements in technology have introduced more sustainable options. You now have access to recyclable and biodegradable plastic films, which address some of these concerns.

Compared to materials like glass or metal, plastic film requires less energy to produce and transport. This lower energy consumption contributes to a smaller carbon footprint. However, improper disposal of plastic film can lead to pollution. Recycling programs and waste management strategies play a vital role in mitigating this issue.

Paper-based packaging is often considered more eco-friendly, but it has its drawbacks. The production of paper involves deforestation and high water usage, which can harm the environment. Glass and metal, while recyclable, consume significant energy during their production and recycling processes.

By choosing recyclable or biodegradable plastic film, you can balance cost-effectiveness with environmental responsibility. These options allow you to reduce waste and support sustainability efforts without compromising on performance or affordability.

Applications and Usability of Plastic Film

Versatility in Industries

Plastic film serves a wide range of industries due to its adaptability and functionality. You can find it in food packaging, where it preserves freshness and extends shelf life. Its moisture-resistant properties make it ideal for protecting perishable goods like fruits, vegetables, and meats. In the medical field, plastic film is used to create sterile packaging for instruments and supplies, ensuring safety and hygiene.

The construction industry also benefits from plastic film. Builders use it as a vapor barrier to prevent moisture damage in walls and floors. In agriculture, farmers rely on plastic film for greenhouse coverings and crop protection. These applications highlight its ability to meet diverse needs across sectors.

Retailers and e-commerce businesses use plastic film for shipping and product protection. It provides a lightweight yet durable solution for wrapping items securely. This versatility makes it a go-to material for industries that prioritize efficiency and cost-effectiveness.

Convenience and Adaptability

Plastic film offers unmatched convenience in packaging and handling. Its lightweight nature makes it easy to transport and store. You can fold or roll it into compact forms, saving space and reducing logistical challenges. This feature is especially valuable for businesses managing large inventories.

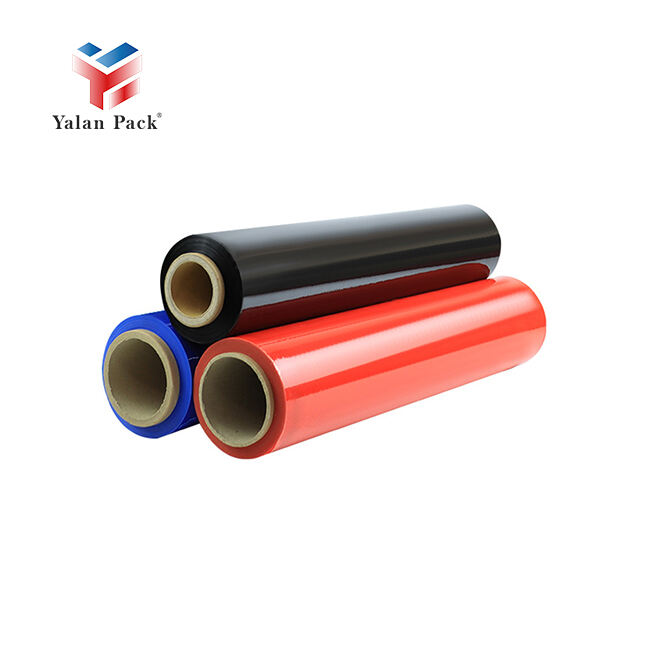

The adaptability of plastic film allows you to customize it for specific purposes. Manufacturers can produce it in various thicknesses, colors, and finishes to suit your needs. For instance, you can choose transparent film for visibility or opaque film for privacy. Its flexibility ensures that it fits products of different shapes and sizes without compromising protection.

Sealing plastic film is simple and effective. Heat-sealing technology creates airtight closures, which help maintain product quality. This adaptability extends to branding as well. You can print logos, instructions, or designs directly onto the film, enhancing your product's appeal and marketability.

Plastic film’s usability also includes its compatibility with automated packaging systems. You can integrate it into high-speed machinery, streamlining operations and reducing labor costs. This efficiency makes it an indispensable material for businesses aiming to optimize their processes.

Environmental Considerations of Plastic Film

Recyclability and Sustainability

Recycling plays a vital role in reducing environmental impact. When you choose plastic film, you gain access to materials that are increasingly recyclable. Many types of plastic film, such as polyethylene, can be processed at recycling facilities. This allows you to divert waste from landfills and contribute to a circular economy. By participating in recycling programs, you help extend the lifecycle of these materials and reduce the demand for new raw resources.

Sustainability efforts have also led to innovations in plastic film production. Manufacturers now create biodegradable and compostable options. These alternatives break down more easily in natural environments, offering a solution to concerns about long-term waste. You can select these eco-friendly versions to align with consumer preferences for sustainable practices. This choice not only supports environmental goals but also enhances your brand’s reputation.

Educating yourself about proper disposal methods is essential. Recycling guidelines vary by location, so understanding local requirements ensures that your efforts are effective. By taking these steps, you actively support sustainability while continuing to benefit from the cost-effectiveness of plastic film.

Waste Reduction Strategies

Reducing waste starts with efficient material usage. Plastic film requires less material to achieve the same protective qualities as bulkier alternatives. This efficiency minimizes the amount of packaging waste generated. When you use less material, you lower disposal costs and reduce the strain on waste management systems.

Reusing plastic film offers another way to cut down on waste. Many industries repurpose it for secondary uses, such as protective coverings or storage solutions. This practice extends the material’s usefulness and reduces the need for additional resources. You can adopt similar strategies to maximize the value of your packaging materials.

Advancements in technology have also introduced lightweight designs without compromising durability. These innovations allow you to use thinner plastic film while maintaining its protective properties. This approach further reduces waste and aligns with sustainability goals.

Supporting initiatives like closed-loop recycling systems can amplify your impact. These systems collect used plastic film, recycle it, and reintroduce it into production. By participating in such programs, you contribute to a more sustainable packaging ecosystem. These strategies demonstrate how you can balance environmental responsibility with practical packaging needs.

Plastic film proves to be a cost-effective packaging material due to its affordability, durability, and versatility. You can rely on it for applications where lightweight, protective, and adaptable solutions are essential. Industries like food, retail, and agriculture benefit greatly from its efficiency and practicality.

When balancing economic and environmental factors, you should consider recyclable or biodegradable options. These choices allow you to reduce costs while supporting sustainability. By understanding its strengths and limitations, you can make informed decisions that align with your packaging needs and environmental goals.